CS Instruments Flow Meter for Compressed Air & Industrial Gas

CS Instruments Flow Meter คือเครื่องมือวัดอัตราการไหล (flow rate) สำหรับระบบ compressed air และก๊าซอุตสาหกรรม ที่ช่วยให้คุณสามารถตรวจสอบปริมาณการไหล วิเคราะห์การใช้พลังงาน (energy monitoring) และควบคุมต้นทุนระบบลมอัดได้อย่างแม่นยำ เหมาะสำหรับโรงงานอุตสาหกรรมทุกขนาดและการติดตั้งในระบบควบคุมอัตโนมัติ

กลุ่มสินค้า Flow Meter จาก CS Instruments

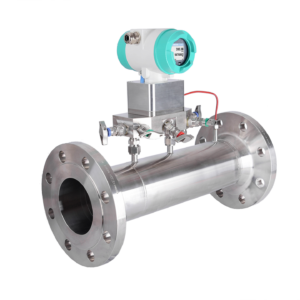

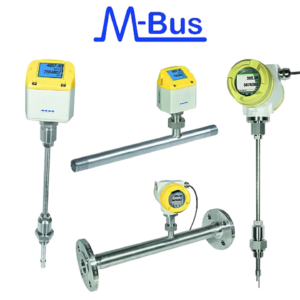

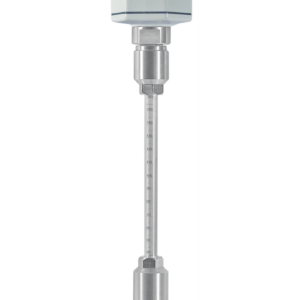

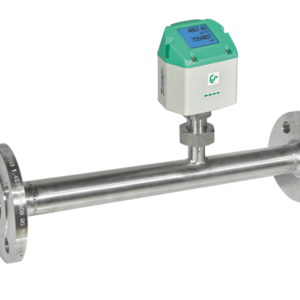

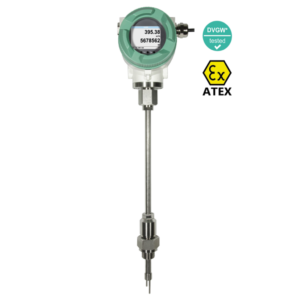

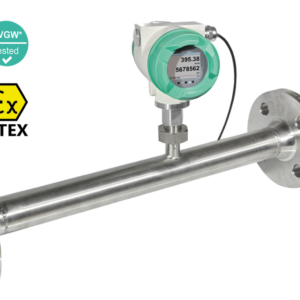

- Thermal Mass Flow Meter สำหรับลมอัดและก๊าซ

- Inline Flow Meter สำหรับการติดตั้งในท่อที่ต้องการวัดปริมาณลมอัด

- Flow Meter สำหรับวัดทั้ง Flow Rate และ Total Volume Consumption

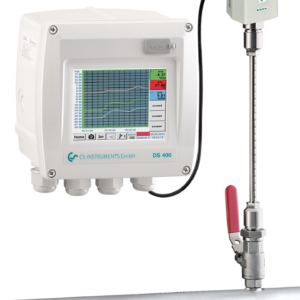

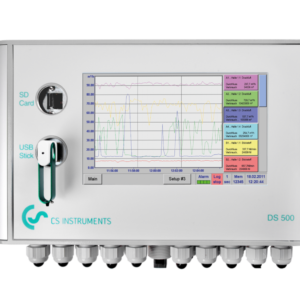

- รองรับการเชื่อมต่อสัญญาณ 4–20 mA, Modbus และ Ethernet

ทำไมต้องใช้ Flow Meter สำหรับระบบลมอัด?

การติดตั้ง CS Instruments Flow Meter ในระบบลมอัดช่วยให้คุณสามารถตรวจสอบการใช้งานจริงของระบบได้แบบเรียลไทม์ วัดค่าการไหลและการใช้พลังงานในแต่ละหน่วย ช่วยวิเคราะห์การสูญเสียพลังงาน และวางแผนลดต้นทุนการใช้ลมอัดในระบบอุตสาหกรรม

เชื่อมต่อกับโซลูชันอื่นเพื่อการบริหารระบบลมอัดแบบครบวงจร

เพื่อการตรวจสอบระบบลมอัดอย่างมีประสิทธิภาพยิ่งขึ้น คุณสามารถใช้งานร่วมกับอุปกรณ์ในหมวด

Dew Point Sensor

และหมวด

Leak Detection Devices

เพื่อให้การบริหารระบบลมอัดและพลังงานของคุณมีความครบถ้วน และสามารถวิเคราะห์ข้อมูลข้ามระบบได้

เยี่ยมชมหมวดใหญ่ของ

CS Instruments Measurement Tools

เพื่อดูอุปกรณ์วัดคุณภาพลมอัดอื่น ๆ และเลือกโซลูชันที่เหมาะสมกับระบบของคุณ

ENLARGE พร้อมให้คำปรึกษาเทคนิคและโซลูชันครบถ้วนสำหรับ Flow Meter ในระบบอุตสาหกรรม

ติดต่อเราเพื่อขอคำแนะนำและใบเสนอราคา

เรียนรู้เพิ่มเติมเกี่ยวกับ Flow Meter จากแหล่งอ้างอิง:

CS Instruments Official – Flow Meter Overview

Understanding Flow Meters for Compressed Air